In the world of natural dyes, indigo has a place on it’s own. Unlike other dyes, it does not need mordanting and can be applied to the fabric straight after scouring. However, it is still very labour intensive, and patience is still of essence here. The dye is applied by layers, dipping the fabric repetitively, and oxygenating it between the dips to allow the indigo blue to appear and intensify with every subsequent dip.

One of the many things that we learned during our 10 day advanced course at Buaisou, in Japan, is to rinse and fix the indigo. It might sound like a simple thing, but careful manipulation of the fabric during those steps is paramount to the final effect. The rinsing process involves several cold and hot rinses over 3 consecutive days.

The fabric is finally dipped in a soy milk solution and left to cure, ideally for a few days to let the soy proteins bind to the dye and the fabric. I will then wash, dry, and iron the item, before is ready to be processed and finally shipped, thus the incompressible delay in completing the orders.

Like me, you will have to learn patience and ultimately enjoy your purchase even more, knowing it has been created with loving care 🙂

First dip

.. and out it goes..

Second dip

Third dip

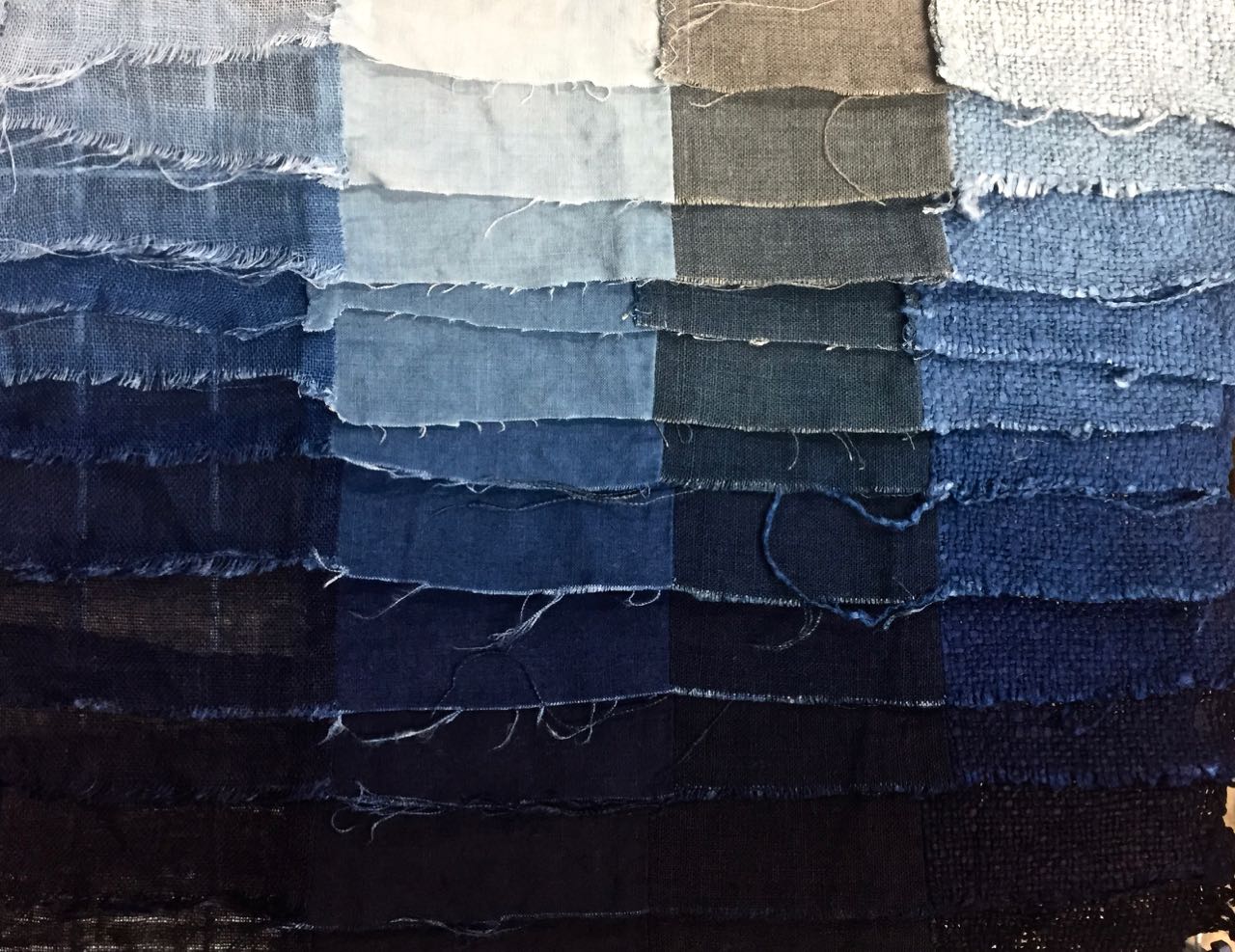

Colour chart

Colour chart